ALUSTEP 500, aluminium honeycomb core and fibreglass skins, the best solution for marble weight reduction

STEP series panels are applied in the stone sector to lighten marble and natural stones, as a reinforcement and support structure for mosaics or in the restoration sector. Due to their lightness, these panels can be used in buildings interiors as a marble support for floors and worktops. In addition, they are used in boat and mega yachts interiors where lightness combined with high mechanical properties becomes a key point in this sector.

Technical Features

This panel offers unique characteristics since it combines lightweight with high mechanical properties. The application of these panels for example permits huge savings as far as weight and thickness of the slabs of natural stones, such as marbles and granite and mosaics are concerned. In this way, also costs can be reduced.

A – SKINS IN BIDIRECTIONAL GLASS FIBRE FABRIC

500 g/m2 impregnated with epoxy resin

B – CORE IN ALUMINIUM HONEYCOMB

Alloy series 3000*) with hexagonal cells

Diameter: Ø1/4”, Ø3/8”,**

Thickness Foil: from 50 to 70 microns

Thickness starting from 4 mm to 80 mm

* To Aluminium alloy series 3000 belong: Aluminium alloy 3003, Aluminium alloy 3005, Aluminium alloy 3103, Aluminium alloy 3104

** Ø3/8” on request

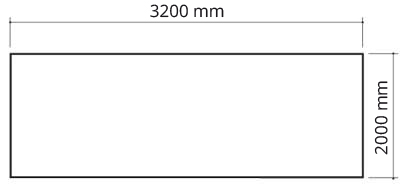

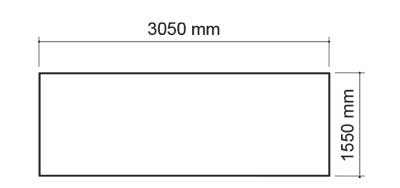

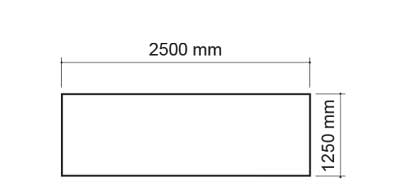

DIMENTIONS

APPLICATIONS

Lightening Marble Mosaics

Yachts and Shipbuilding

Floor Panels

Interiors

Buildings and Restorations

Technical data sheet for standard panels (dimensions, materials and special finishes on request) | |||||||

TECHNICAL CHARACTERISTICS OF PANEL | |||||||

thickness of the panel mm | from 5 to 100 | ||||||

panel size mm | standard 1250 x 2500 / 1500 x 3050 on request up to 1600 x 4000 | ||||||

thickness’ tolerance mm | ± 0,5 | ||||||

dimension’s tolerance mm | ± 30 | ||||||

skins’ thickness mm | 0,4 | ||||||

glass fibre skin | Glass fibre Plain 500 gr/m² 600 tex | ||||||

Impregnation | Epoxy resin | ||||||

honeycomb alluminium alloy | 3000 series / 5000 series | ||||||

thickness of honeycomb foil μm | 50 and 70 | ||||||

diameter of honeycomb Ø = mm | from 3 to 19 | ||||||

honeycomb density Kg/m³ | from 20 to 163 | ||||||

adhesive for aluminum honeycomb | Epoxy Resin | ||||||

PANEL PHYSICAL AND MECHANICAL PERFORMANCES | |||||||

type panel (some examples) mm | 5 | 10 | 15 | 20 | 25 | 30 | 35 |

panel weight ‡ Kg/m2 | 2,5±0,2 | 2,7±0,2 | 3,0±0,2 | 3,3±0,2 | 3,6±0,2 | 3,8±0,2 | 4,1±0,2 |

compressive stabilised strength MPa ** ‡ ASTM C 365-365 M Mpa | 2,9 ± 0,3 | ||||||

maximum load ** ‡ ASTM C 393 † N | 180±20 | 400±40 | 600±60 | 800±80 | 1.000±100 | 1.200±100 | 1.400±100 |

deflection at maximum load ‡ ASTM C 393 † mm | 55±6 | 28±3 | 18±2 | 13±1 | 11±1 | 9±1 | 8±1 |

skins E Elastic Modulus ** Mpa | 28.000±1.000 | ||||||

moment of inertia I ** mm4/m | 4.000 | 18.400 | 40.000 | 76.000 | 120.000 | 174.000 | 240.000 |

middle resistance to peeling ** ‡ ASTM D1781-98 (2012) | > 500 N/76 mm or >60 Nmm/mm | ||||||

oad distributed on a 1000 x 1000 x 20mm supported on 2 sides kg | 300 | ||||||

Marble/Panel Bonding Test according to ASTM D 4501 | suitable bonding, the substrate (stone) breaks down | ||||||

deflection recorded on 1000 x 1000 x 20mm panels supported on 2 sides under 300 kg weight distributed on the whole panel surface mm | 18 | ||||||

maximum service temperature ** °C | – 40 / + 70; on request + 85 | ||||||

thermal expansion coefficient ** °C-1 | 1,5 * 10-5 / 1,5 mm for ΔT 100 °C for 1 meter length | ||||||

* Tested by Certificating Institute

** Tested by Internal Laboratory

*** Approximate value

† Sample dimension with 4 support points (L, W) 540×540

‡ All values refer to a panel made of aluminum honeycomb with a cell diameter 6 mm 56 kg/m3 and epoxy adhesive